Modern PVC noise barrier walls are leading the way to more cost-effective and sustainable solutions

Industrial sites tend to make noise and mitigating that noise makes those workplaces safer for their employees and, if they have neighbors, makes the industrial site more amenable to the surrounding residents or businesses. As urban areas grow and industries find themselves in more mixed-use areas, noise mitigation has become a rapidly growing sector.

Today’s lightweight PVC sound wall solutions are a breakthrough

Lightweight PVC noise barrier wall systems, like those from AIL Sound Walls, are revolutionizing the industrial noise-control solutions sector.

PVC sound walls now replacing early “durable concrete solutions”

Early sound walls and enclosures were often made from wood, metal, concrete or other composite materials. Over time, the drawbacks of noise barriers made from these soundproofing wall materials became evident as they began to show wear and degradation from weather and other factors. Wood was prone to rot; metal could fall victim to rust; concrete was susceptible to cracking and break-up from repeated freeze/thaw cycles. In fact, many of the earlier sound walls made from those industrial materials are being replaced today by more sustainable and effective solutions such as lightweight PVC sound walls.

Take a look at the benefits of the AIL Sound Wall systems

Modern innovations in noise barrier wall systems, like those from the AIL Sound Walls R&D team, are leading the way to more cost-effective and sustainable sound barrier wall construction solutions compared to other soundproofing wall materials.

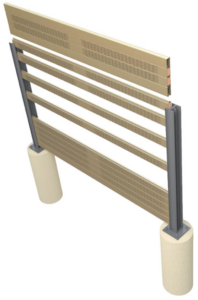

Lightweight PVC construction

- Tongue and groove panels stack within steel posts

- Quick and easy to install

- Adapts easily to site variations and design requirements

- Available as Silent Protector (Absorptive) or Tuf-Barrier (Reflective) noise barrier walls

Lower installed cost

- Smaller foundations mean lower foundation costs

- Install with local labor and less lifting equipment

- Adaptable to a variety of footing types

- XL Series offers panel lengths of up to 16′ (4.9 m) for fewer panels, posts and foundations

More resilient and sustainable material

- Made from recycled and recyclable PVC

- Highest percentage of recycled material

- A readily renewable and recyclable product

- Minimized water consumption in manufacturing

- Optimized shipping for reduced CO2 emissions

- Long product lifespan

- Smaller footprint, better urban land use

Durable and low-maintenance

- PVC systems are impervious to rain, snow and ice and are unaffected by de-icing salts

- Will not rust, rot or stain

- Wind load tested for hurricane-force winds

- Meet accelerated test requirements for durability

- Graffiti- and tagging-resistant

- Designed to meet applicable design codes (AASHTO, IBC, CSA)

- Meet ASTM F3459-21 Standard Specification for PVC Exterior Profiles used for Sound Walls

Smart owners, specifiers, planners and engineers look at the total cost of the sound barrier wall over its full life cycle and soon discover that lightweight PVC sound barrier walls, like those from AIL Sound Walls, are the go-to choice for a better ROI. Not only do they offer a better bottom line on the project installation costs, but they also set the stage for many decades of low-maintenance service.

AIL Sound Walls are available in both absorptive or reflective industrial noise-control solutions

Unlike noise barriers made from the other materials, AIL Sound Walls are available as either Silent Protector (Absorptive) or Tuf-Barrier (Reflective) systems. With Sound Transmission Class (STC) ratings of up to 39, these sound barrier systems are engineered for maximum sound reduction of environmental or ambient noise such as traffic, manufacturing, industrial or commercial noise. AIL Sound Walls offer enhanced aesthetic solutions with a variety of attractive colors and even woodgrain textures and finishes.

Nimble AIL Sound Walls are ideal for complexities of industrial, municipal and energy sector sites

With their design flexibility, lighter weight and corresponding smaller foundations, AIL Sound Walls are popping up on more and more industrial, municipal and energy sector sites throughout North America. They often need to navigate around complex layouts and tight spaces, and they frequently need to be mounted to existing concrete slabs or adjoin other structures. At other times, they need to incorporate access gates, vents, utility ports or other requests. The AIL Sound Walls Engineering and Design teams are well-versed in working with customers and their consultants to come up with the most effective and efficient noise barrier wall solutions for specific sites.

Here are some examples of AIL Sound Walls in industrial, municipal and energy sector noise-control solutions:

Texas pumping station required a lightweight noise barrier wall solution

A water/wastewater pumping station in Pasadena, Texas, backed onto a residential neighborhood and an effective sound-mitigation solution was needed. Durable and long-lasting AIL Sound Walls were already a known entity in the area, as we had previously designed and supplied solutions for three Pasadena schools and a similar pumping station in San Antonio. At the outset of the project, we worked closely with the consultant, H R Green, to design cost-effective foundations and lay out the barriers to work around driveways and provide access to the equipment. View Project Profile >

Equipment enclosure integrates with an existing slab at Florida water reclamation facility

The plant’s proximity to a college and to residential neighborhoods required an effective sound barrier enclosure around an array of gas compressors. Together, we worked out the optimal layout for the enclosure (which included two main doors, a large double gate for access, wiring/lighting and many apertures for utility lines and ventilation) and the mechanics of integrating our system into the slab design while still having sufficient resistance to Florida’s high wind loads. Our system’s lightweight PVC construction makes it much easier to integrate with slabs, roofs, retaining walls, parapets and other structures. View Project Profile >

PVC system has the right stuff for New Jersey electrical utility switching station

PSE&G is the electrical utility provider for most of New Jersey. They required an effective sound barrier wall solution to mitigate sound and visual impacts on neighbors from their new White Horse switching station in the Trenton area. Our design was altered to accommodate grade changes along the run of the wall and the need for grounding tabs to be welded to our posts, as per the electrical utility requirements. Our PVC panels are ideal for this type of application, being a non-conductive material. Our PVC sleeve/cap compression fitting post system encapsulates our steel posts, further preventing conduction.

AIL Sound Walls are a great fit for a rather compressed natural gas site in California

Residential neighbors of a Compressed Natural Gas (CNG) station owned by the City of Norwalk, CA, were complaining about the facility’s loud pressurized emissions. The city needed to find a sound barrier solution that could install easily within the complex layout of the tight urban site. Because of its lightweight PVC construction, Silent Protector was able to nimbly navigate in and around the various tanks, compressors and lines. And, because of its high-performance absorptive panels, Silent Protector truly lived up to its name. With a Sound Transmission Class (STC) rating of up to 36 and a Noise Reduction Coefficient (NRC) rating of 1.0 — the highest achievable rating — how could it not? View Project Profile >

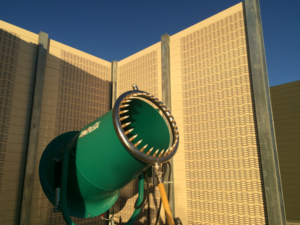

Equipment enclosures earn their salt at California desalination facility

Our project to design and supply five equipment enclosures to a desalination plant in Cambria, CA, has been earning us kudos from neighbors and project partners alike. The large machines that spray excess water into the air, allowing it to evaporate faster, were very noisy, to the dismay of local residents. Once our Silent Protector (Absorptive) enclosures were in place, their positive comments came filtering back to us. So, too, did those of our customer, CDM Smith, who were as pleased with the community feedback as they were with our timely responses, quick turn-around and competitive pricing. View Project Profile >

An AIL Sound Walls Technical Sales Representative can help you save time and money on your noise-control solutions

The AIL Sound Walls team is experienced in finding alternative solutions that offer your projects the same functionality and quality at a better value. We call it value engineering and it is a systematic, organized approach to providing necessary functions in a project on a faster schedule and at the lowest cost. It promotes the substitution of materials and methods with less expensive alternatives without sacrificing functionality, performance or safety.

Our value-engineered solutions for noise barrier walls could include:

- Wider post spacing through our Silent Protector XL or Tuf-Barrier XL Series

- Specialized footing designs and pile systems to reduce materials and labor

- Custom attachments and fittings to simplify structure-mounted solutions

There’s an AIL Sound Walls specialist ready to help you value engineer a better solution for your sound-mitigation project — and the sooner they get involved in the process, the more you may save. Call toll-free 1-866-231-7867 to get started.