August 19, 2021

Controlling unwanted noise from distribution and logistics centers has become a significant and growing part of our business, with several large sound barrier wall projects in our portfolio.

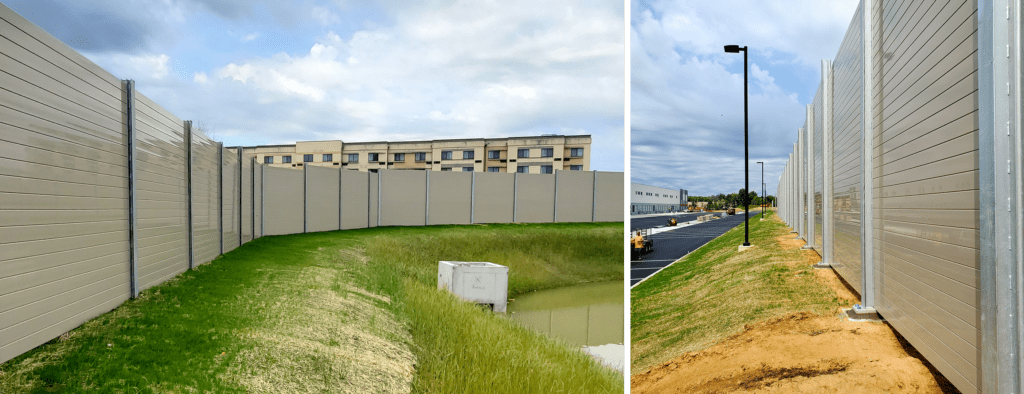

This project for the Westampton Logistics Center was completed in two phases. Phase One included two walls: one near the main entrance to block sound for a nearby hotel, and one L-shaped wall in the back right corner of the site. Phase Two was an addition to the wall at the back.

Phase Two used our new, longer Tuf-Barrier XL Series

All walls were constructed using our Tuf-Barrier (Reflective) product, but the second phase was able to take advantage of our new Tuf-Barrier XL panels, which can reach spans of up to 16′. That meant fewer panels, posts and foundations for a lower installed cost.

Contractor develops faster foundation method

Kudos to the contractor on the project, Extreme Builders, for coming up with an innovative way of attaching to the concrete footings that allowed them to speed up their installation.

We worked very closely with the Extreme team, including having a thorough preconstruction meeting, sequenced manufacturing to meet their schedule and on-site technical support throughout the installs.

They reached out to us with some positive post-project feedback and have recommended us for future projects.

“We were very pleased to collaborate with the AIL Sound Walls team again on this project. They kept pace with us every step of the way and the product was very easy to work with. The overall quality of their system is second to none and will truly stand the test of time for many years to come.”

— John Noone, Vice-President, Extreme Builders

We had recently value engineered another large sound barrier wall solution using Tuf-Barrier XL for the IPT Railroad Logistics Center in nearby Florence, New Jersey.